Industrial Upgrading Coating First

Intelligent leadership in industrial upgrading

Industry & Company News

Industry Updates and Company News

/ Steady Innovation, Smart Future - Naxau 2025 Annual Tailgate Successfully Held

Naxau's 2025 annual event was successfully concluded in Pinghu, Jiaxing. The conference comprehensively reviewed the breakthrough achievements of the company in the past year, and clearly drew a strategic blueprint for future development driven by technological innovation. In the past year, NanoShield has realized a number of major breakthroughs in the field of core technology: While successfully developing the Indian market, the company also achieved fruitful internal incentives: specially awarded 100,000 RMB “Grassroots Innovation Award”, and awarded a number of invention patents to the R&D team, fully recognizing the wisdom and value of the frontline staff....

Detailed information

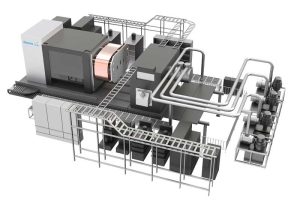

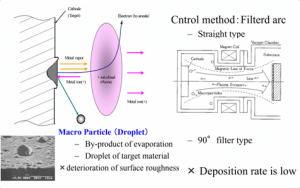

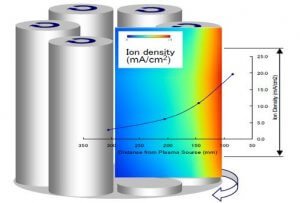

Naxau Presented at the 2025 China Solid State Battery Developer Forum

February 27-28, by the yunfan solid state battery host, hunan province battery industry association and Shanghai frontier new energy power supply technology research institute co-sponsored "2025 China solid state battery developer forum" in jiangsu suzhou grand opening, zhejiang nashi composite collector company engineer Guo Bei was invited to give a speech, made a "PVD vacuum Guo Bei, an engineer from Zhejiang Naxi Composite Fluid Collector Company, was invited to give a speech and made a presentation on "Progress of PVD Vacuum Lithium Coating Technology in Lithium Metal Anode Application of Solid State Battery", and showed up at the forum with the cutting-edge composite collector composite copper foil technology and anode lithium supplement. The forum brings together solid state battery developers,...

![[Naxau] New Journey-New Leap-2023 Annual Meeting Ceremony [Naxau] New Journey-New Leap-2023 Annual Meeting Ceremony](https://www.naxauam.com/wp-content/uploads/2024/01/纳狮2023年会-810x486.jpg)

[Naxau] New Journey-New Leap-2023 Annual Meeting Ceremony

Chairman's Speech Mr. Yuan Ansu, Chairman of Naxau, gave a New Year's speech on the stage, reviewing the achievements of 2023, thanking all the shareholders and colleagues for their support, and expressing the outlook for 2024, with a new start in the New Year and a new level of excellence. On the evening of January 12, 2024, Naxau held its 2023 Annual Meeting Ceremony. The atmosphere of the ceremony was active and warm, Naxau colleagues talked about friendship, looking forward to the future, a new year, a new starting point, on the basis of our achievements last year, we have more confidence and determination to create a better tomorrow. ...

In 2023, Naxau Academician Workstation was evaluated as [Excellent Academician Workstation] by Jiaxing City, and became a bridge to introduce SALD Semiconductor's leading technology and friendship between China and foreign countries.

Judith Driscoll, Fellow of the British Academy of Engineering, Fellow of Trinity College, Cambridge University, Professor of Materials Science and Editor-in-Chief of the SCI journal APL Materials, with a focus on semiconductor composites, is a leading expert in the field of nanomaterials research worldwide. From 2020, Naxau will employ Driscoll as the company's Chief Scientist and will establish an Academician Workstation. Through the cooperation with the academician and his team, Naxau is in line with the world's leading technology, researching and developing new semiconductor materials and coating equipments, jointly cultivating internationalized scientific and technological talents, as well as...

Naxau Vacuum Coating Processing - Naxau AM

Naxau Vacuum Coating Processing - Naxau AM