PVD coating for high hardness and abrasion resistant plastics

Naxau has a specialized injection molding coating process research and development team, with big data support of 12,000 successful cases from 2,000+ famous users as of 2018. We are familiar with the product injection molding process and understand the impact of plastic temperature distribution, injection speed, pressure, position and other process parameters on coating quality, so that we can help customers solve various injection molding problems more efficiently.

High-precision anti-adhesive Coating Programs

Surface hardness: 2000HV

Coating thickness: 0.01-0.02mm

Abrasion resistance: ★★★★

Corrosion resistance: ★★★★★

Anti-stick capability: ★★★★

Applicable working conditions: high-speed, high-pressure, sticky material; for transparent optical products, all kinds of lenses, light guide plate, etc.; commonly used optical products plastic: PMMA, PC, COC, COP, CR-39, etc.;

High hardness glass fiber carbon fiber Coating Programs

Surface hardness: 3500HV

Coating thickness: 0.005-0.07mm

Abrasion resistance: ★★★★★

Corrosion resistance: ★★★

Applicable conditions: glass fiber, engineering plastics containing 70% and below; carbon fiber, content of 50% and below; such as: PA, PC, PBT, PPS, PAR, PEI, PEEK and so on;

multilayer membrane structure Longer lifespan

Patented SPARK Nano Technology

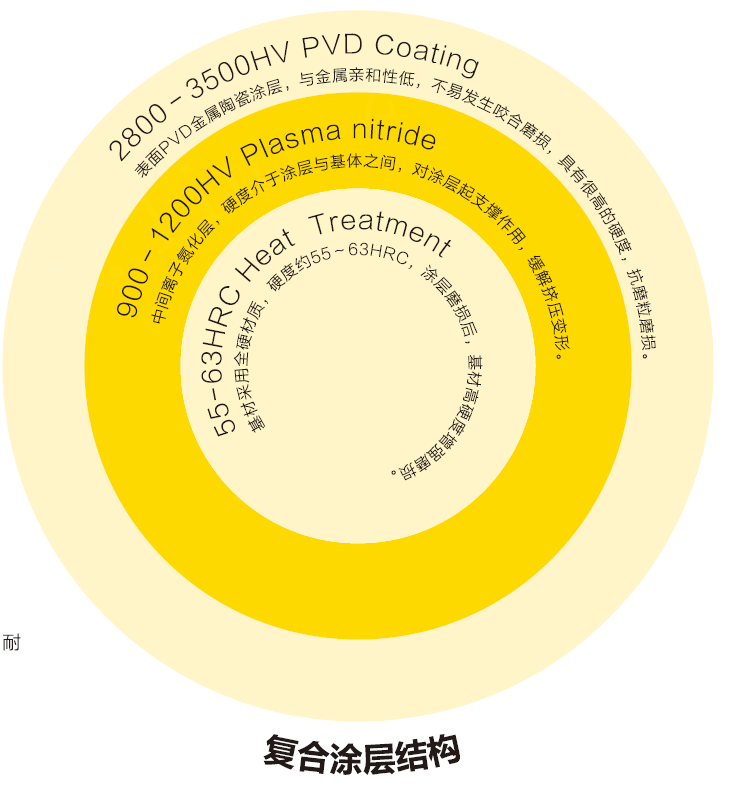

Naxi adopts a combination of vacuum nitriding and PVD titanium plating surface treatment process, which not only provides substrate surface support for the highly hard titanium plating layer, but also realizes the stress transition from soft to hard. Nasi multi-layer film, more dense lattice structure; and no cracks more resistant to corrosion.

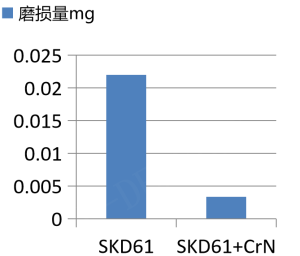

Issues: Test equipment: pin-on-disc friction and wear tester (type SFT-2M)

Issues Disc speed: 150r/min Total travel: 163m

Issues: Test load: constant load 470g

Agenda item: TOKYO JAPAN P600

▇ Steel and hardness: SKD61, hardness 52HRC

▇ Coating thickness: 3.8um, hardness 2200HV

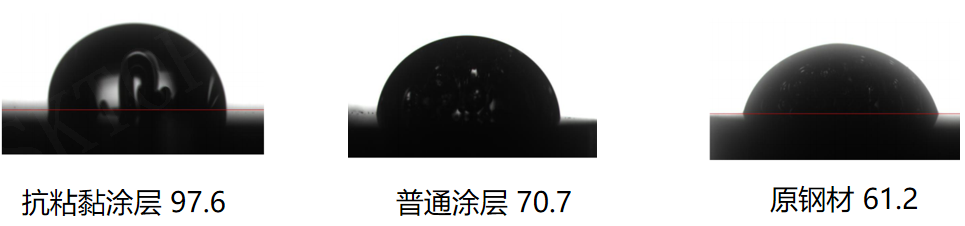

Anti Sticky Material Test - High Temperature Wetting Angle

Anti adhesive material test

Test conditions:

Agenda item: PC AD5503 (Teijin)

Issues to be addressed: Nashion anti-adhesive coating, normal coating, uncoated sample

▇ Surface roughness of specimen: Ra 0.2um

▇ Temperature: 300°C

Typical coating types for injection molding

| protective layer | Hardness: HV | Film thickness: μm | antioxidant temperature | coefficient of friction | Appearance Color | Suitable for processing materials |

| CrN | 1800-2200 | 10-20 | 700 | 0.4 | ash gray | Applicable to transparent optical products, all kinds of lenses, light guide plate, etc.; commonly used plastics for optical products: PMMA, PC, COC, COP, CR-39, etc. |

| CrAl+ | 3000-3500 | 5-7 | 1000 | 0.5 | dark gray | Glass fiber type, engineering plastics containing 70% or less; carbon fiber type, containing 50% or less; These plastics are PA, PC, PBT, PPS, PAR, PEI, PEEK, etc. |

| DLC | 2000 | 1-3 | 350 | 0.1 | Black | Injection mold type; corrosion resistance, anti-adhesion; |

Comparison of DLC and Ta-C properties

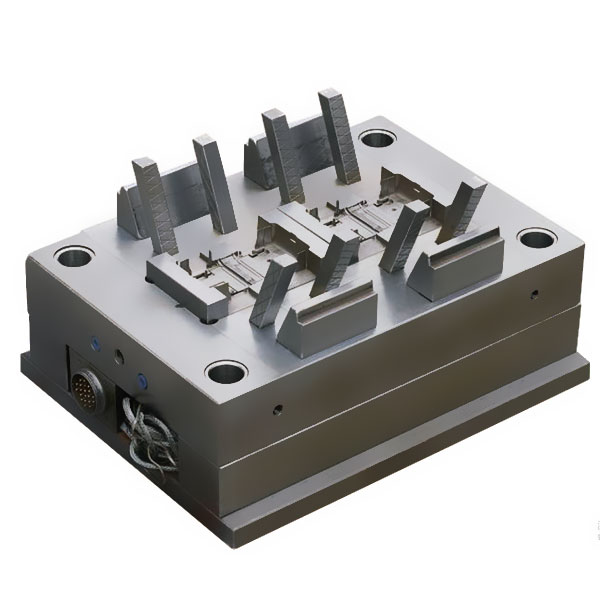

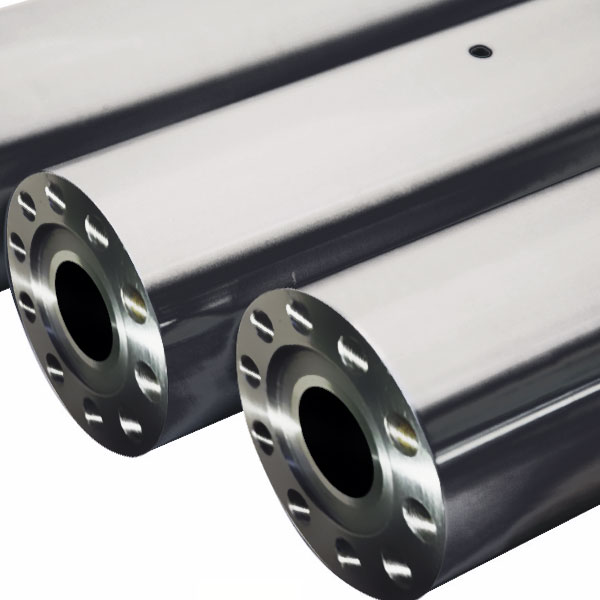

PVD injection mold applications

Injection Molds-Injection Screw Coating FAQs

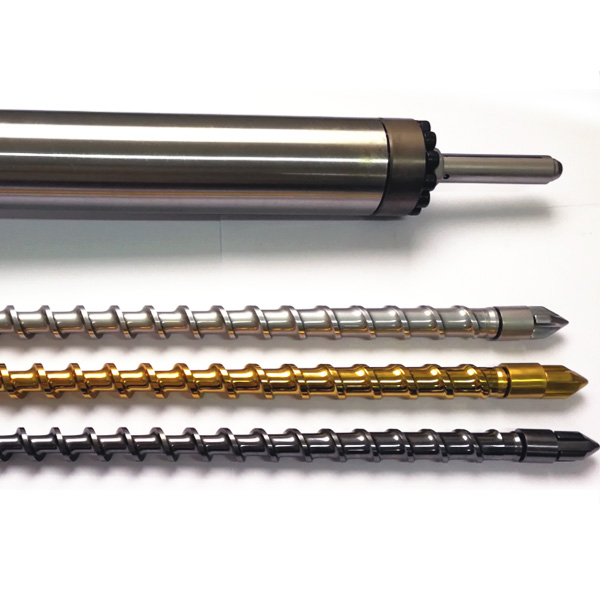

Whether to use chrome plating or PVD titanium plating for injection molding screws should be considered according to specific application scenarios, performance requirements, cost considerations and environmental requirements. Currently, injection molding screws are mainly plated, while PVD technology is mainly used for injection molding of high carbon fiber, glass fiber and other hard wear-resistant materials.PVD titanium plating in the application of injection molding screws have many limitations

Naxau Vacuum Coating Processing - Naxau AM

Naxau Vacuum Coating Processing - Naxau AM