High Power Droplet-Free High Arc PVD Vacuum Equipment and Advanced Tooling Coating Solutions

NanoShield Spark high gloss arc technology is widely used in 3C high gloss knife coating applications. Compared to traditional overcritical arc multi-arc ion plating and even the latest Hipims high frequency magnetron sputtering, droplets are noticeable and film defects are significantly reduced.

01 Comparison of common PVD equipment processes

NanoSpark's droplet-free technology is another breakthrough: TiN coatings, for example, have a thickness of 2.5um, a deposition rate of 0.5um/h, Ra <0.05um, and a hardness of 34Gpa.

| multi-arc ion plating | magnetron sputtering | Nash Spark Highlight Arc |

|---|---|---|

| Limited target materials High surface roughness > Ra0.2 High dissociation rate >60% High deposition rate >1um/h | Abundant sputtering materials Low surface roughness Ra0.05 Low dissociation rate 20%-40% Low deposition rate 0.35um/h | Abundant sputtering materials Low surface roughness <Ra0.05 Low dissociation rate >90% Low deposition rate 0.5um/h |

02 High light arc process characteristics

- High Arc Coating: Harder coating with fewer droplets

- High Gloss Arc Coating: Reduced surface roughness reduces surface wettability and provides an anti-sticking effect.

- High light arc coating: fewer coating droplets, fewer defects, denser coatings

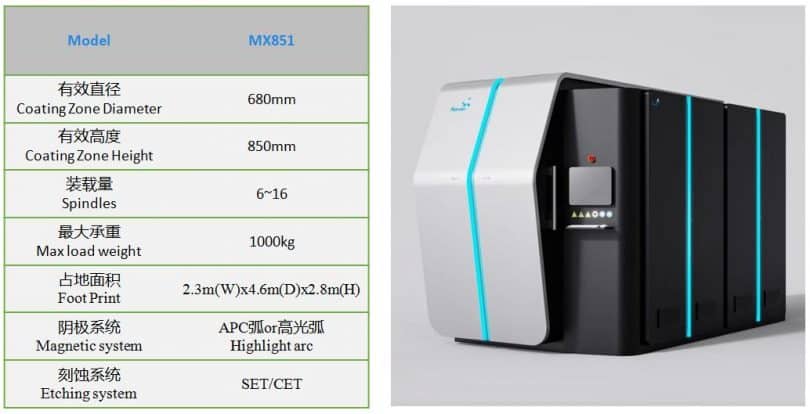

03 Nasi High Arc Vacuum Coating Equipment

Nasi PVD, PECVD, DLC process vacuum coating equipment, suitable for tool coating, mold coating, parts coating and medical bio-coating. Provide the whole plant hardware and software turnkey output program, and provide "accompanying" service, really help customers talk about vacuum coating oh equipment with good use up.

04 Application of Ta-c coatings for high light arc tools

utilizationTa-C coatingIt can effectively improve tool life, reduce machining costs and improve product quality.

Naxau Vacuum Coating Processing - Naxau AM

Naxau Vacuum Coating Processing - Naxau AM