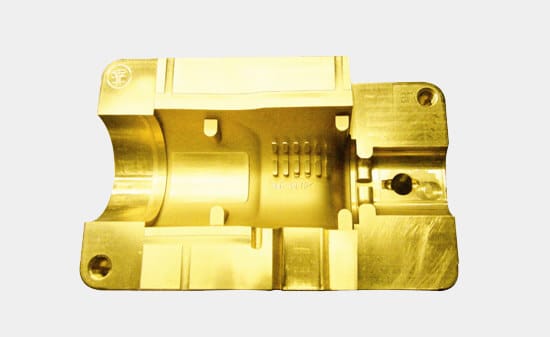

Plastic molds

Introduction Plastic molds are relatively expensive due to the complexity of the results that determine the difficulty of processing, so improving the life of the mold is a major topic ......- Industry Applications Stamping Mold | Plastic Molds | Die Casting Molds | Stretch Molds

The main challenges of modern plastic molds

● Most of the plastic injection molded products are appearance parts, which have the most stringent requirements on the surface quality of the products, and any problems and defects on the surface of the mold will be fully reflected on the injection molded products.

● Plastic molds have the problem of corrosion at the same time, in addition to the problem of insufficient surface hardness such as surface scratches and abrasion. Most of the wear-resistant coatings on the market are not corrosion-resistant.

● Plastic mold surface will often do a variety of etching, nibbling flowers, mirror polishing and other treatments, most of the coating technology on the market is too large particles, which will affect the original treatment of the plastic mold of a variety of patterns and mirrors, plastic molds need a more sophisticated coating.

Advantages of Naxcoat on plastic molds

:: In response to the challenges of modern plastic molding, NACI has developed the under-application "SEACOR" coating series. Heco is the world's first superhard coating that is both corrosion and temperature resistant.

● SEACOR Coatings has successfully taken advantage of SPARK 6's droplet-free technology. The droplet-free SEACOR Coatings can completely maintain the precise etching and high mirror surface of various surfaces of plastic molds, and the perfect craftsmanship of mold makers is protected by the hardness of SEACOR Coatings.

● The low coefficient of friction L-coating on the surface of SEACOR coatings also improves plastic flow, increases mold filling capacity, and makes demolding easier.

Naxau Vacuum Coating Processing - Naxau AM

Naxau Vacuum Coating Processing - Naxau AM