Facing the future-Nashville New Journey-2021 Shenzhen New Energy Vehicle Industry Summit Forum

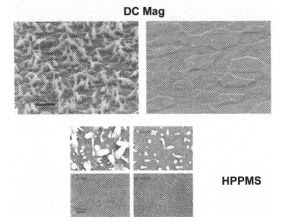

4314May 28, held in Shenzhen, "2021 New Energy Vehicle Industry Development Summit" came to a successful conclusion, the summit focuses on the development of the three electric systems and advanced manufacturing key technologies, intelligent manufacturing digital transformation, automotive lightweight and environmentally friendly materials, on the market layout, technological upgrading, material applications, intelligent manufacturing and other topics Discussions on market layout, technology upgrading, material application, intelligent manufacturing and other topics. Naxi continuously develops new PVD nano-coating process to help...

View Full Version Naxau Vacuum Coating Processing - Naxau AM

Naxau Vacuum Coating Processing - Naxau AM