Industrial Upgrading Equipment First

Intelligent leadership in industrial upgrading

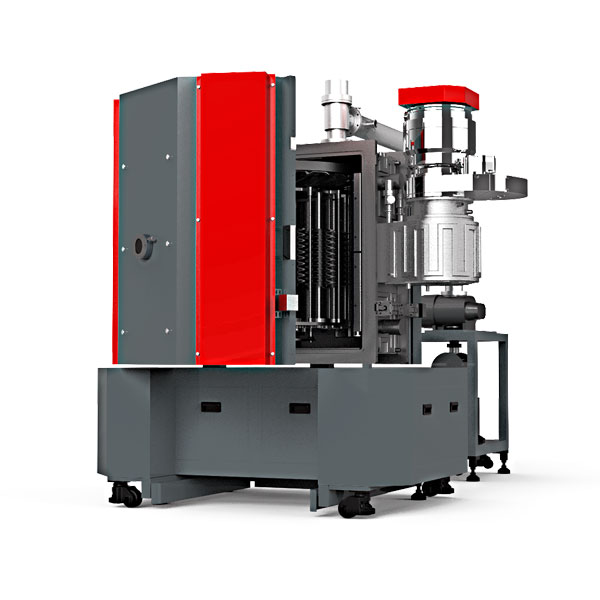

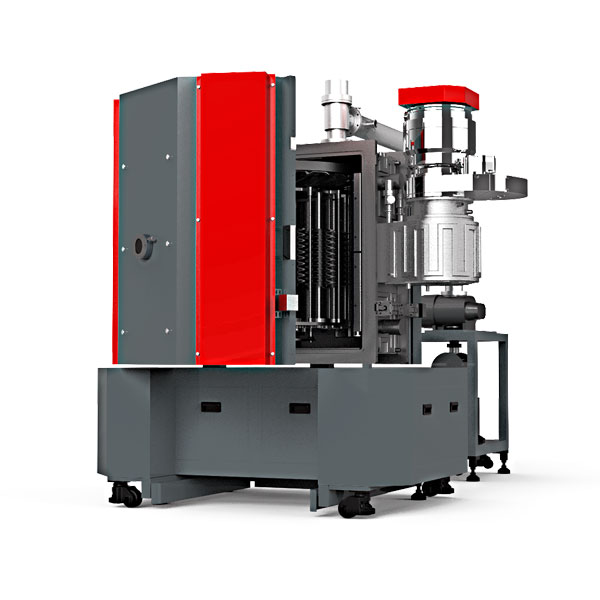

Customized Vacuum Coater

product & project

Naxau customized series of vacuum coating systems are designed for NACS SPARK platform, evaporation coating, multi-arc ion plating, sputtering/templating, and other applications.HIPIMSThe company has a wide range of plasma technologies, such as PeCVD, PeCVD, etc.; and it can be customized with cavity size, composite ionomer technology, film thickness monitoring, etc., which is suitable for R&D-type flexible production and research and development.

Naxau has 20 years of experience in vacuum coating technology research and development, and has always taken technology and service as the basis of the company. Naxau can provide one-stop service, including vacuum coating center construction, production line peripherals, vacuum coating system, coating quality control system, personnel SOP training, coating process orientation development and lifetime maintenance service.

- Sputtering, multi-arc composite coating process; complex coating series including DLC, amorphous, multi-layer film can be realized

- Intelligent host computer control system for customized development of coating processes.

- Nanny escort service, one-stop solution to coating center operation problems

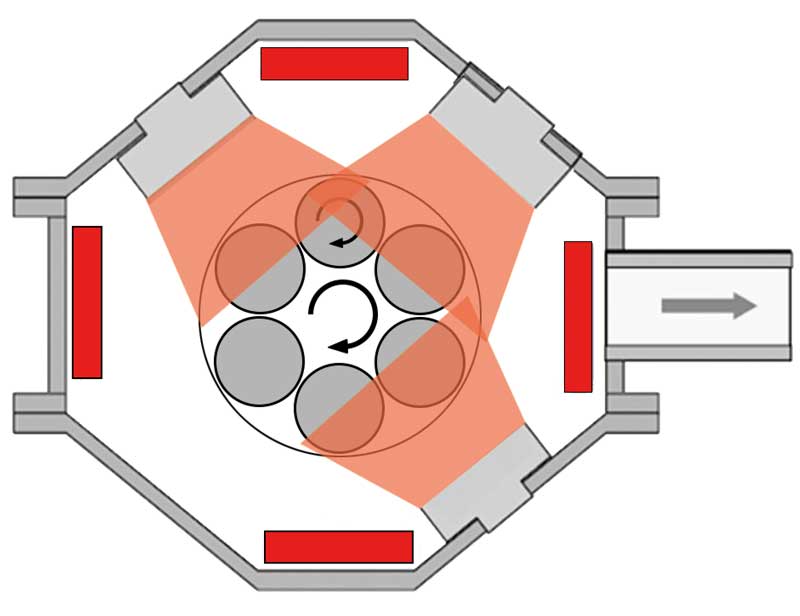

Mastery of core arc source technology - highly customizable

Adjustable magnetic field design ensures higher target utilization. Has a faster arc spot running speed, smaller arc spot, higher dissociation rate, smaller droplets, more conducive to the dissociation of low melting point targets.

Advantages of Laminators

- Various cutting-edge technologies such as droplet-free high light arc, Hims, JVD high power, etc.

- Deposition of multi-component, multi-structure, amorphous and other coating systems

- Multiple coating technologies can be combined

- High deposition rate, high film thickness uniformity, low coating defects

Dual-etching technology for dramatically improved bonding::

Based on more than 20 years of continuous operation and improvement, Naxau has developed a plasma etching technology SET and CET. Proper etching of the tool surface to achieve a clean and revitalized interface prior to coating is critical to a successful coating result. Etching requires the removal of surface contaminants such as metal oxides, water vapor, micro-oils and sweat debris. Etching also reactivates the surface and opens up molecular chains to induce ionic bonding during the coating process.

Wind Power Bearing Project

Wind Power Bearing Project Industry-University-Research Cooperation

In 2022, Naxau has successfully delivered the first PeCVD self-lubricating coating coater for wind turbine bearings, which significantly improves the life of wind turbines and reduces maintenance costs. Naxau, helping China's green power business to develop sustainably.

- DLC load-bearing self-lubricating coating series

- DLC, ta-C, Mo-containing super lubrication series, silicon doped coatings, etc.

.jpg)

Institutional Cooperation

Institutional Cooperation Transformation of Results

On October 31, 2023, Naxau undertook the transfer of two nano-hard coatings from the National Key Laboratory of High Performance Tools (Guangdong University of Technology) and signed a contract for the implementation of the transfer of the rights valued at RMB 1,200,000 yuan. In addition, Naxau also donated a set of multi-functional high-performance coating equipments valued at 5 million RMB to GDIT, which includes CET/SET side-to-side-through glow discharge etching system, CVC electrodeless magnetically-controlled arc source system, and UFC high light arc source system.

turnkey project

turnkey project

One-stop shop for vacuum coating equipment, coating process, peripheral production equipment suggestions, personnel training, plant planning, and other complete coating plant mass production program.

Naxau vacuum coating equipment is one of the industry's most reliable production outputs. Multiple plasma deposition technologies can be compounded on a single machine.

Naxau Vacuum Coating Processing - Naxau AM

Naxau Vacuum Coating Processing - Naxau AM