Roll-to-Roll Flexible Coating Technology

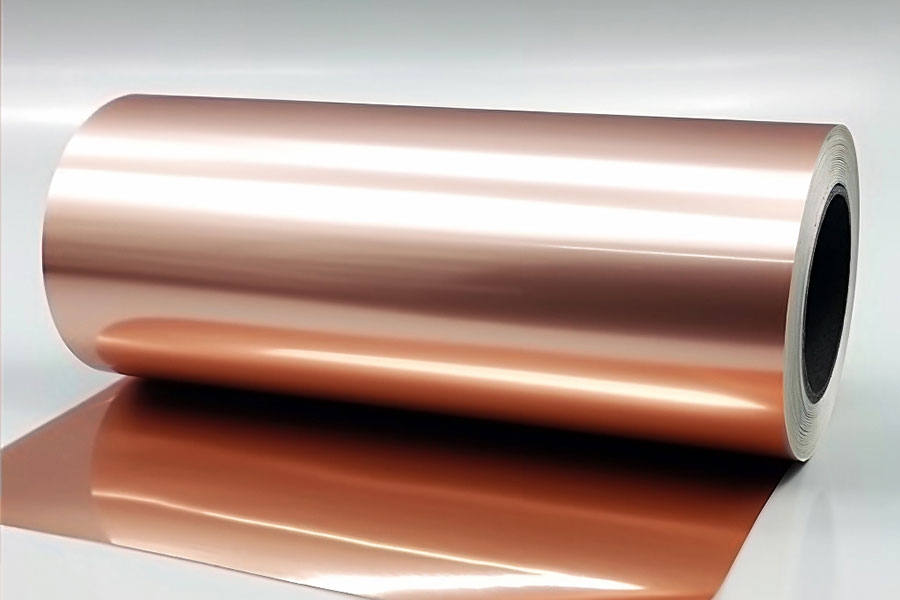

0.5-5μm flexible copper plating and other metal films, the optimal thickness for multiple applications. Suitable for: chip packaging, lithium batteries, photovoltaic, communications, etc.

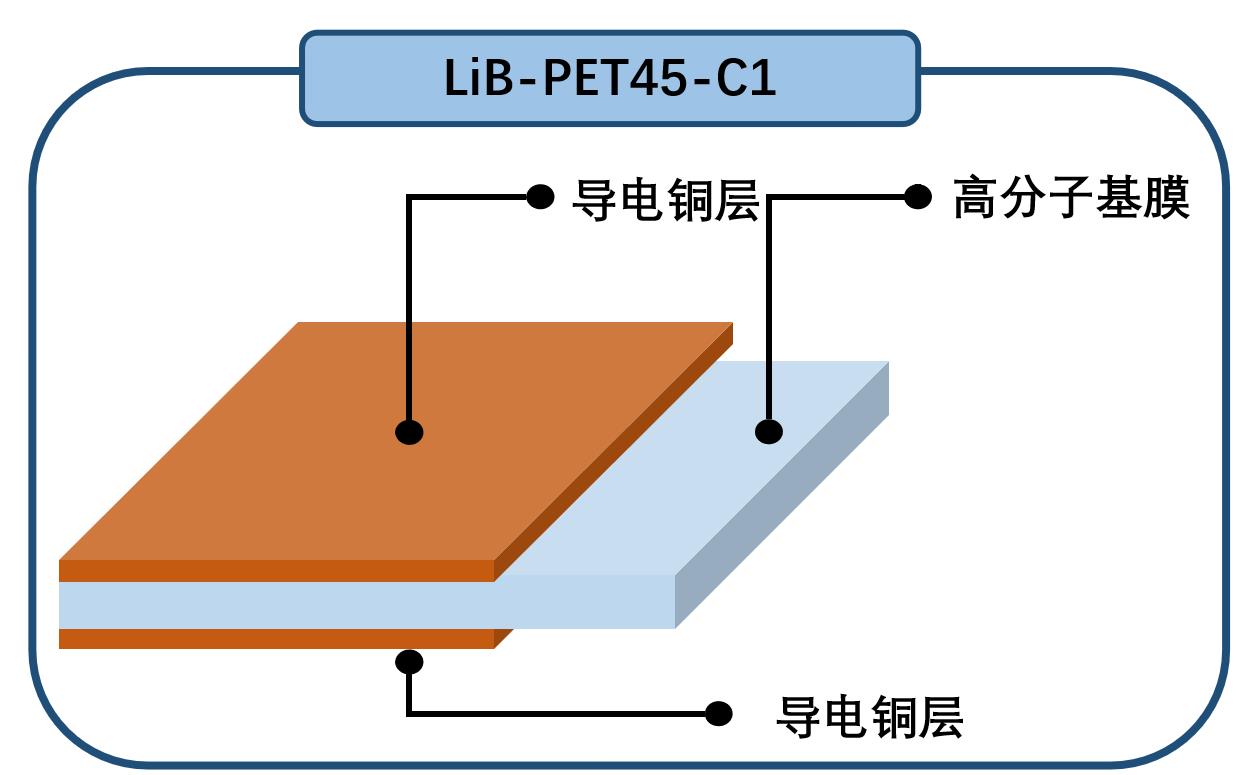

Lithium Battery Composite Collector

Copper Composite Foil / Vacuum Plated Aluminum Foil / Vacuum Plated Copper Foil

Vacuum Deposition | One Step | Double Coating | 0.5 -2 micron

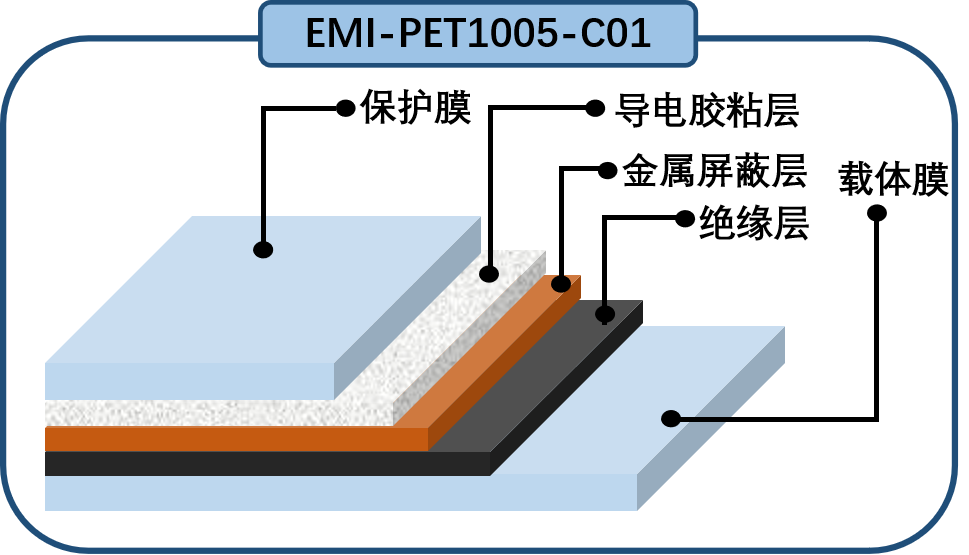

Electromagnetic Shielding Film EMI

Limit the electromagnetic wave to a certain range, effectively suppress electromagnetic interference.

Vacuum Evaporation | Dielectric Constant: 2.8dk | Shielding: 82dB | 0.1-0.3 micron

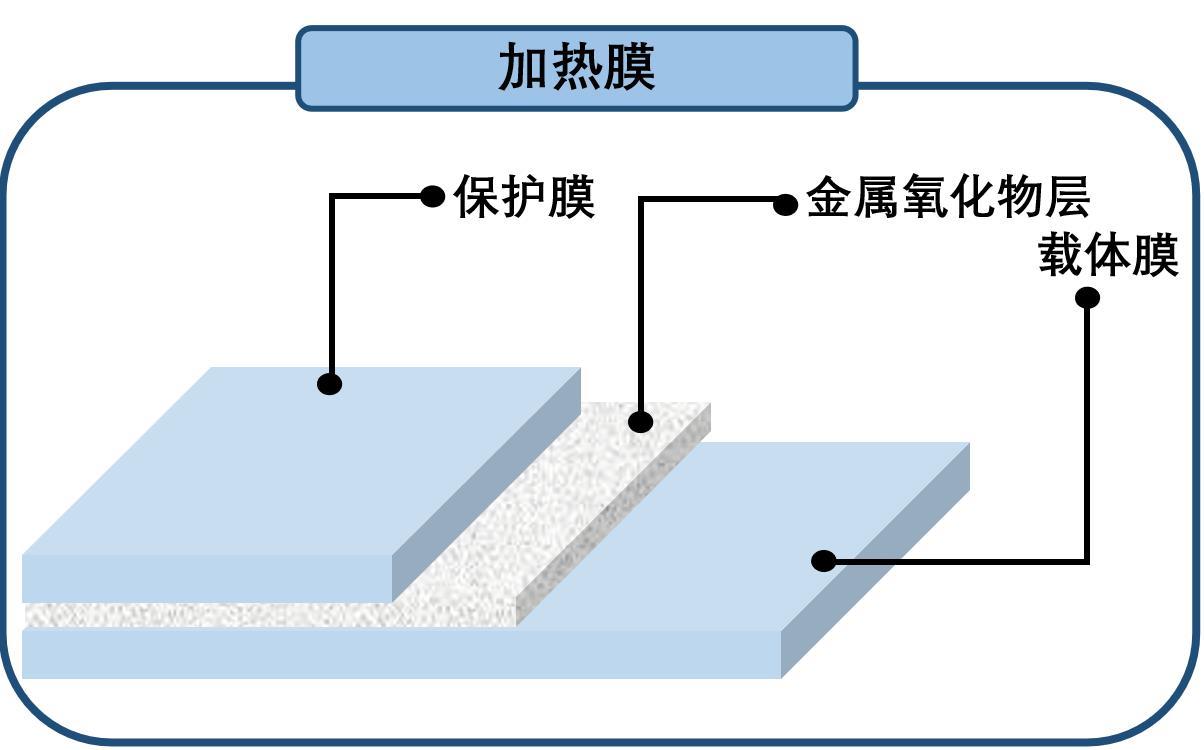

Conductive heating film

PI Heating Film / PTC Heating Film / Heat Dissipation Film

Vacuum Deposition | Metal Oxides | Composite Copper | 0.5 -2 micron

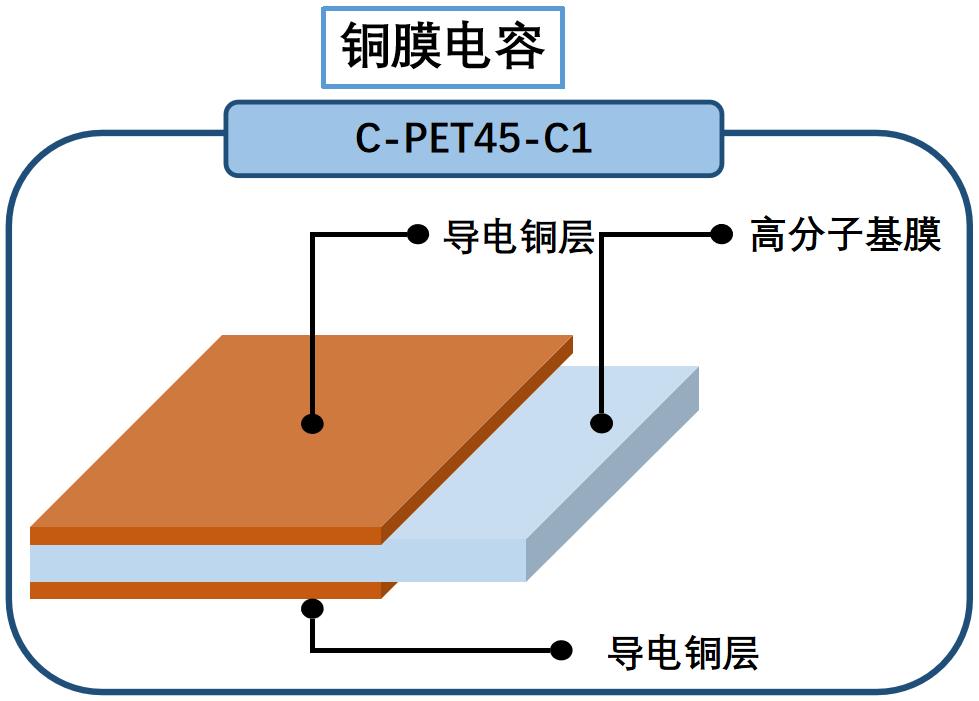

capacitor film

The advantage of metallized film capacitors is the "self-healing" property. Naxion realizes one-step double-sided deposition of Al/Cu on polyester film.

Vacuum Deposition | Type C1: 1μmCu+4.5μmPET+1μmCu, total thickness 6.5μm

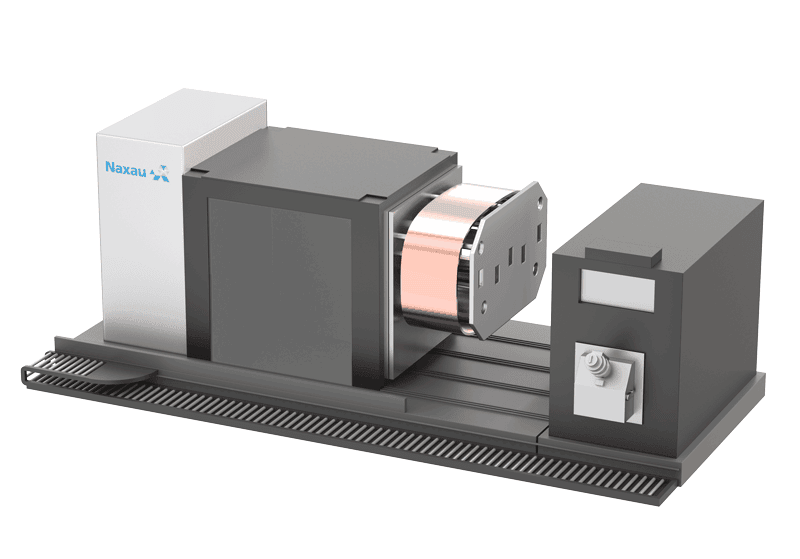

Ultra-low profile HVLP copper/aluminum foil coated on both sides on substrates such as PET/PP within 6 microns.

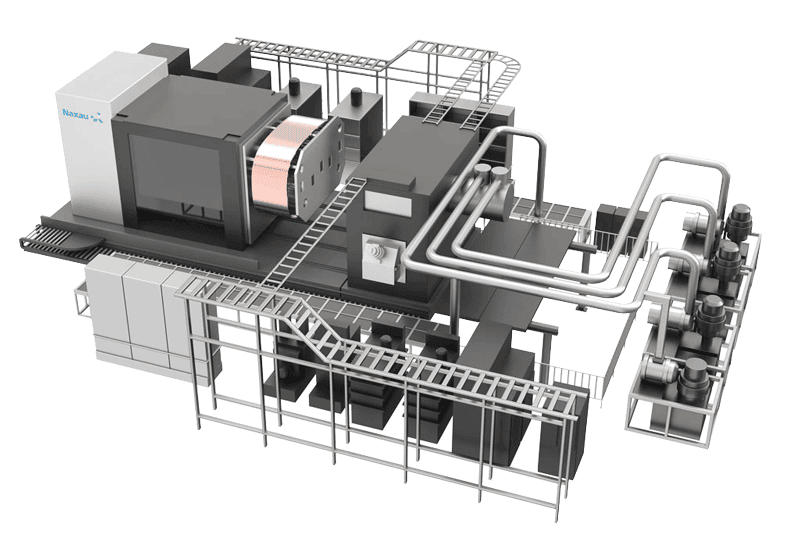

Model R650 can coat Cu film on both sides of PET/PP/PI substrate (without Cr primer) to form high density and strong adhesion metal composite foil, and is equipped with high precision winding system, thermal management system, tension control system, strip deflection system, plasma pretreatment and integrated anti-oxidation system, online film thickness control and process control system to realize high quality and efficient coating. The effect of high quality and high efficiency coating is realized.

HVLP Copper Foil, will be the new hot spot in the field of high-speed and high-frequency electrical signals such as 5G.

JVAD Coating Technology

JVAD Coating Technology

In 2023, NanoShield officially launched JVAD high-power liquefied vacuum coating technology, which can realize rapid PVD coating of one micron a minute.JVAD technology, is expected to break the application and price boundaries of PVD, and extend the hard functional film to more applications. The rapid thickening of PVD coating has a price comparable to that of traditional electroplating, but with higher film hardness, bonding force, corrosion resistance, film thickness uniformity and many other advantages of PVD technology.

Currently, Naxau can provide JVD coating prototyping and customized JVD coating equipment and multi-chamber rapid production line, welcome to inquire!

Ultra Low Profile Copper Foil Related Applications

High Frequency High Speed, Cell Phone EMI, FCCL

PET, PI film as a substrate to complete the flexible line manufacturing, instead of imported high-precision FCCL. advantages: ultra-thin (3-5um PI) copper foil, no Cr bottoming, improve the accuracy of etched lines.

Expandable direction: Optical AR winding coating, high melting point metal winding coating, solid state battery winding coating with pure Li electrode.

Ultra-thin film copper plating products for COF applications

PVD Copper coating on Ultra Thin film

COF (Chip On Flex, or, Chip On Film), often referred to as crystal laminated film, is the integrated circuit (IC) fixed in the flexible circuit board on the grain soft film construction technology, the use of flexible additional circuit boards as a packaged chip carrier will be a combination of the chip and the flexible substrate circuits, or a single reference to the unencapsulated chip of the flexible additional circuit boards, including tape-and-reel package production (TAB substrate. The process is called TCP), flexible board connection chip assembly, flexible IC carrier board packaging.

Lithium Complementary Coil Coater

Lithium-supplemented Coil Coating Equipments

Lithium-ion battery lithium replenishment technology is an important means to improve battery energy density. Nash utilizes vacuum lithium plating film technology and roll-to-roll cycle operation to realize one-step lithium plating on copper foil. Ten years of safe operation records can ensure the stability and excellent cycle performance during the subsequent use of the battery.

solid state batteryNegative electrode coated with lithium film.

Naxau Vacuum Coating Processing - Naxau AM

Naxau Vacuum Coating Processing - Naxau AM