JVAD Coating Technology

JVAD Coating Technology

In 2023, Naxau officially launched JVAD high-power vacuum coating technology, which can realize rapid PVD coating of one micron a minute.JVD technology, is expected to break the application and price boundaries of PVD, and promote hard functional films to more applications. The rapid thickening of PVD coating has a price comparable to traditional electroplating, but with higher film hardness, bonding force, corrosion resistance, film thickness uniformity and many other advantages of PVD technology.

Currently, Naxau can provide JVD coating prototyping and customized JVD coating equipment and multi-chamber rapid production line, welcome to inquire!

JVAD Technology Core Advantages

Fast Coating Ultra Thick PVD

Leading Cost Reduction Technology, Breaking Through Application Boundaries

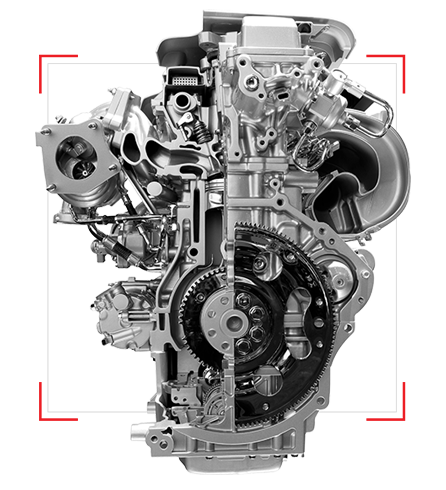

In the fields of machinery manufacturing, aerospace, petrochemical, mining and metallurgy, agricultural machinery, textile and printing and paper making, mechanical wear and tear often co-exist with corrosion. On the premise of requiring a low-cost process, surface treatment coatings are required to be wear-resistant and corrosion-resistant. Nash JVAD hard coating technology, compared with traditional electroplating, supersonic spraying, laser cladding and cladding process, with high hardness, high density, high bonding force and no need for post-processing advantages, is gradually reducing the cost of continuous popularization.

Naxau Vacuum Coating Processing - Naxau AM

Naxau Vacuum Coating Processing - Naxau AM