How to Choose PVD Blade Coating-2021

Bronze Lathe Blade Coating

Depending on the specific shape of the insert, the machine parameters (process, speed, etc.), the material to be machined (heat treatment process, hardness, etc.), different PVDs are recommended.Blade CoatingThe

For end customers, batch processing materials are fixed, you can choose stainless steel, high temperature alloys and other specialized blade coating. For distributors who need to prepare stock, they can consider general-purpose coatings to cope with the needs of different processing materials.

New Plasma Enhanced Arc Source Technology Platform Technical Advantages

- Advantage 1--Better magnetic field design, higher dissociation rate, fewer droplets, smoother and more delicate surface of coated film.

- Advantage 2 - Stronger arc source energy, denser film particles, higher coating hardness

- Advantage 3 - Less coating stress, no tip coating removal

| Coating Name | color | Coating hardness (HV) | Antioxidant temperature ℃ | coefficient of friction | Coating thickness μm | Application Recommendations |

|---|---|---|---|---|---|---|

| Composite TiN | golden yellow | 2000 | 500 | 0.25 | 2-3 | General-purpose steel processing; better adhesion resistance |

| TX-S | golden yellow | 3500 | 800 | 0.25 | 4-6 | General steel, cast iron, stainless steel universal coating |

| AML | Purplish black | 3300 | 800 | 0.3 | 3-4 | General steel processing |

| AMR | Bronze color | 4200 | 1000 | 0.3 | 2-3 | For stainless steel, high hardness materials; wear-resistant and high temperature resistant |

| AMT | grizzly | 4000 | 1200 | 0.3 | 3-4 | For hard-to-machine materials such as high-hardness, nickel-based alloys, etc. |

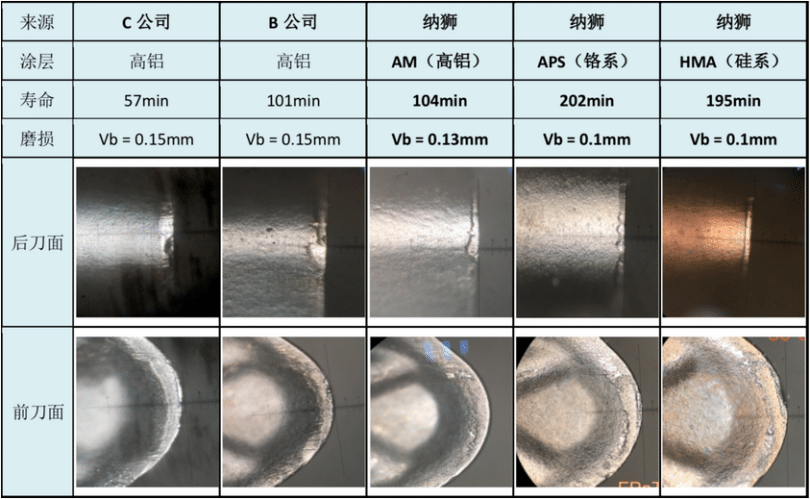

Naxau CNC Insert Cutting Test Experiment

- Experiment:

Interrupted turning was used to check the wear and impact resistance of the coating with the following cutting parameters:

Material: 718HH (hardness 40~42HRC)

Vc = 100m/min

f = 0.25mm/r

Ap = 1mm

Dry cutting

Strong intermittent (4 slots)

reach a verdict

In medium-speed dry cutting roughing, with strong impact conditions, turning and machining HRC40 mold steel, Naxau insert coatings have shown very good wear and impact resistance.

For the same type of high alumina coating, our HAM coating performs better than the high alumina coatings of Company B and Company C in terms of impact resistance and heat resistance on the front blade surface and wear resistance on the back blade surface.

Naxau Vacuum Coating Processing - Naxau AM

Naxau Vacuum Coating Processing - Naxau AM