cutting tool Coating Programs

Coating Solution for Cutting Tools

Knife Tool Coating SolutionsCutting tool coating solution

Naxau Mold Coating Wizard

| protective layer | Coating Description | Hardness (HV) | film thickness (μm) | antioxidant temperature (°C) | coefficient of friction | Appearance Color | Field of application |

| TN | TiN | 2000 | 1.0~3.0 | 600 | 0.25 | gold color | General steel processing of taps |

| TiCN | TiCN | 3800 | 1.0~3.0 | 450 | 0.2 | grizzly | Stainless steel and normal steel material processing of taps |

| TiAlN | TiAlN | 3000 | 1.0~3.0 | 800 | 0.4 | Purplish black | General mold steel cutting processing |

| AM | AlTi-based | 3300 | 1.5~3.0 | 900 | 0.4 | grayish black | HRC≤40 mold steel, stainless steel cutting processing |

| ASM | AlTiSi-based | 3500 | 1.5~3.0 | 1000 | 0.35 | grayish black | HRC≤45 mold steel, stainless steel cutting processing |

| HM | TiSi-based | 3800 | 1.0~3.0 | 1100 | 0.3 | Bronze color | Stainless steel, mold steel, titanium alloy cutting processing |

| HMA | TiSi-based | 4200 | 1.5~3.0 | 1100 | 0.3 | Bronze color | Titanium alloy, powder metallurgy steel, HRC30~55 mold steel processing |

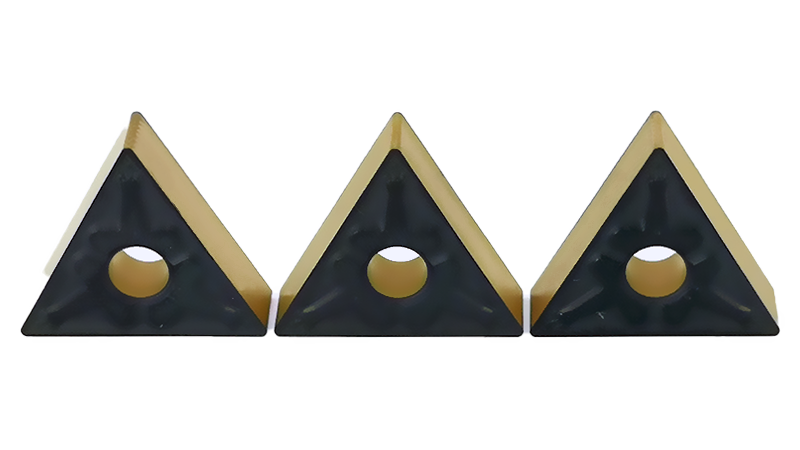

| CV | TiAlSi based | 3500 | 4~6 | 1000 | 0.3 | gold color | Imitation CVD coating for turning inserts |

| APS | AlCr-based | 3500 | 1.5~3.0 | 1100 | 0.3 | grayish black | HRC ≥ 40 mold steel cutting processing, stainless steel processing |

| AG | AlCr-based | 3500 | 0.5~1 | 1000 | 0.3 | grayish black | Stainless steel highlighting, high-gloss processing of special high-gloss |

| AMS | TiAlCr-based | 3600 | 1.0~5.0 | 1000 | 0.3 | grayish black | Hobbing, gear shaping cutters for various conditions, milling cutters, inserts HRC ≤ 50 mold steel, cast iron, etc. |

| AMT | AlCr-based | 4000 | 1.0~3.0 | 1000 | 0.3 | grayish black | High-speed dry cutting of hobbing and gear shaping tools |

| AML | AlTi-based | 3000 | 1.0~5.0 | 1000 | 0.4 | Black | HRC≤45 mold steel, stainless steel cutting processing |

| AMR | AlTiSi-based | 3500 | 1.0~5.0 | 1100 | 0.35 | Bronze color | For hardened steel above HRC55 |

| AU | AlTiSi-based | 3500 | 1.0~5.0 | 1100 | 0.35 | Bronze color | Specialized for PVD coating of stainless steel blades |

| DX | CrAlTi-based | 3200 | 1.0~5.0 | 1000 | 0.4 | grizzly | General purpose for milling and drilling up to HRC55 |

| DA | ZrN-based | 3000 | 1.0~3.0 | 1000 | 0.3 | light golden yellow | Non-ferrous metal processing, stainless steel processing, titanium alloy processing, high temperature alloy processing |

| AMD | AlTiSi-based | 4000 | 1.0~3.0 | 1200 | 0.35 | grayish black | High-hardness mold steel machining, titanium alloy machining, high-temperature alloy machining |

| DH | CrAlSi based | 3500 | 1.0~5.0 | 1100 | 0.35 | Bronze color | Stainless steel milling, titanium cutting |

| DP | AlCr-based | 3200 | 1.0~5.0 | 1000 | 0.3 | grayish black | Hobbing tools for high-speed dry cutting, carbide tools for machining stainless steel, titanium alloy, mold steel |

| DT | AlCrTiSi-based | 3600 | 0.5~3 | 1100 | 0.3 | Bronze color | 52-65HRC high hardness die steel, deharpenable alloys, wear-resistant materials, tungsten-copper alloys, composite materials |

| TX-S | AlTi-based | 3000 | 1.0~5.0 | 600 | 0.35 | gold color | Carbon steel blades up to HRC40 are universal |

| TiB2 | TiB2 | 3000 | 1.0~3.0 | 600 | 0.3 | Greyish white | Non-ferrous metal processing, plastics processing |

High Gloss Arc Tool CoatingDroplet free coating

Chemical Vapor Deposition Coatings

CVD coating

Naxau CVD Chemical Vacuum Vapor Deposition coating services are mainly focused on high hard cutting tools, anti-adhesive/stamping molding and other tooling categories.Naxau CVD can deposit coatings from 5 microns to 20 microns thick, using TiN, TiCN and α-alumina (Al2O3) to form monolayers or multilayers.The CVD deposition process is typically at 900°C or above, with a coating time of 10 hours, and is only for high temperature resistant substrates.

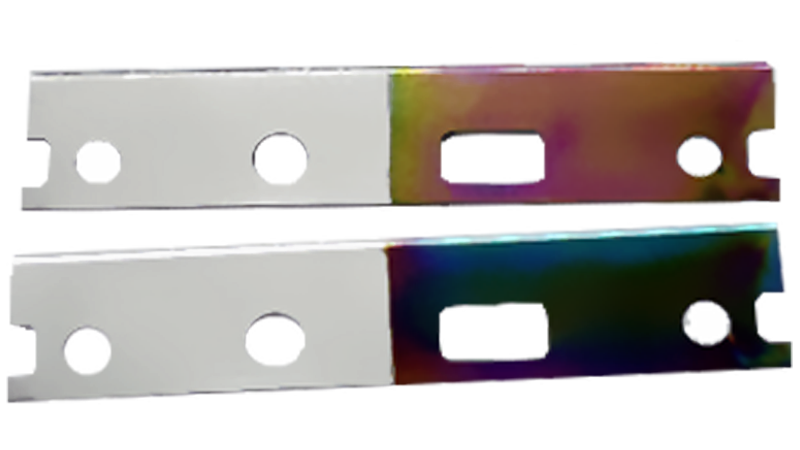

ta-C Coating for Thin Blade Cutters

Thin Blade Tool Coating

Naxau ta-C carbon film series, film thickness 0.2-0.5μm, hardness 3500-6000HV, coefficient of friction 0.1-0.15, low-temperature immersion film within 200℃, suitable for thin-blade knife tool applications. Skills significantly increase the cutting force without reducing the hardness and finish of the substrate, can be widely used in razor blades, lawn mowers, lint cutters, die cutters and other dry cutting conditions.

In addition, for thin-edged tools with high wear resistance requirements, NanoShield has a series of thick-film metal-ceramic films that can increase life by 2-4 times and reduce the risk of chipping.

TiB2 and ZrN for non-ferrous metals

Non-ferrous metal processing

NaxauTiB2 (titanium diboride) coating, 3000HV hardness, prepared by HiPiMS, low stress and high chipping resistance. Particularly suitable for non-ferrous metals (such as aluminum, copper, magnesium and its alloys) processing in the wear-resistant and anti-metal high-temperature corrosion working conditions. And it can realize 300 m/min high speed cutting; reduce 40% or more than traditional carbide.

ZrN chromium nitride coating, also widely used in non-ferrous metal processing and wood processing.

Naxau Vacuum Coating Processing - Naxau AM

Naxau Vacuum Coating Processing - Naxau AM