Array

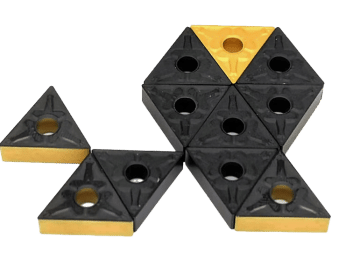

CVD Coating Services

Naxau CVD Chemical Vacuum Vapor Deposition coating services are mainly focused on high hard cutting tools, anti-adhesive/stamping molding and other tooling categories.Naxau CVD can deposit coatings from 5 microns to 20 microns thick, using TiN, TiCN and α-alumina (Al2O3) to form monolayers or multilayers.The CVD deposition process is typically at 900°C or above, with a coating time of 10 hours, and is only for high temperature resistant substrates.

- catalogsCVD Coating Processing Services

| Guide to CVD Coating of Cemented Carbide CNC Tools | |||||||

| protective layer | Coating Description | film thickness (μm) | Coating composition | coefficient of friction | Appearance Color | Field of application | |

| KA | TiN | 13~17 | TiCN+Al2O3+TiN | 0.3 | gold color | For general steel parts | |

| KB | TiCN | 13~17 | TiCN+Al2O3 | 0.4 | Black Diamond | Gray cast iron, ductile iron | |

| KC | TiAlN | 13~17 | TiCN+Al2O3+TiN | 0.4 | two-toned | Mild steel, alloy steel | |

| KD | AlTi-based | 13~17 | TiCN+Al2O3 | 0.4 | pornographic | High overall performance | |

| KE | AlTiSi-based | 9~9 | TiCN+Al2O3+TiN | 0.3 | gold color | Stainless steel and other anti-adhesive steel | |

| Process Characteristics | PVD Physical Vapor Deposition | CVD Chemical Vapor Deposition |

|---|---|---|

| vacuum | 10-2 to 10-4 mbar | Atmospheric pressure or low vacuum |

| temp | 200-450°C | 900-1050°C |

| sedimentation limitation | the law of sight | Any surface that the gas can come into contact with |

| Coating process | Physical vapor deposition | chemical vapor deposition |

| film thickness | 1-7 μm, or customized by NanoLion | 5-12 μm, max. 20 μm. |

| Substrate Limitations | Non-vacuum volatile | Long-term high temperature resistance |

| surface finish | 0.03-0.05μm | Needs to be polished |

| reprocess | No heat treatment required | Tool steels need to be post-treated to modulate hardness |

| edge construction | No stacking of edges | Thick film with sandable edges |

Differences between CVD and PVD coatings

CVD is limited to high-temperature resistant materials, and like PVD coating, the surface of the substrate is smooth and free of oil and rust in order to ensure the bonding of the coating.

Naxau Vacuum Coating Processing - Naxau AM

Naxau Vacuum Coating Processing - Naxau AM